Concrete doesn’t simply take shape on its own, let’s face it. Formwork is useful in this situation. Imagine it as a mould that creates the final appearance of wet concrete. The first thing to get right is the form, whether you’re building beams, slabs or walls. What material has been bearing the weight (literally) in silence for years? plywood.

Plywood Concrete Forms: What Are They?

The first thing to get right is the form, whether you’re building beams, slabs or walls. What material has been bearing the weight (literally) in silence for years? Plywood.

Why Make Formwork Out of Plywood?

Let’s take a closer look. Why plywood instead of plastic or steel?

Sturdiness and Power

Good plywood is durable. It is designed to resist warping and splitting even under the extreme pressure of wet concrete. It manages several pours with ease when properly reinforced.

Economicalness

Plywood is more flexible and less expensive than metal forms. It provides excellent value for money for small to medium-sized projects, particularly if you reuse and maintain it properly.

Concrete Form Plywood Types

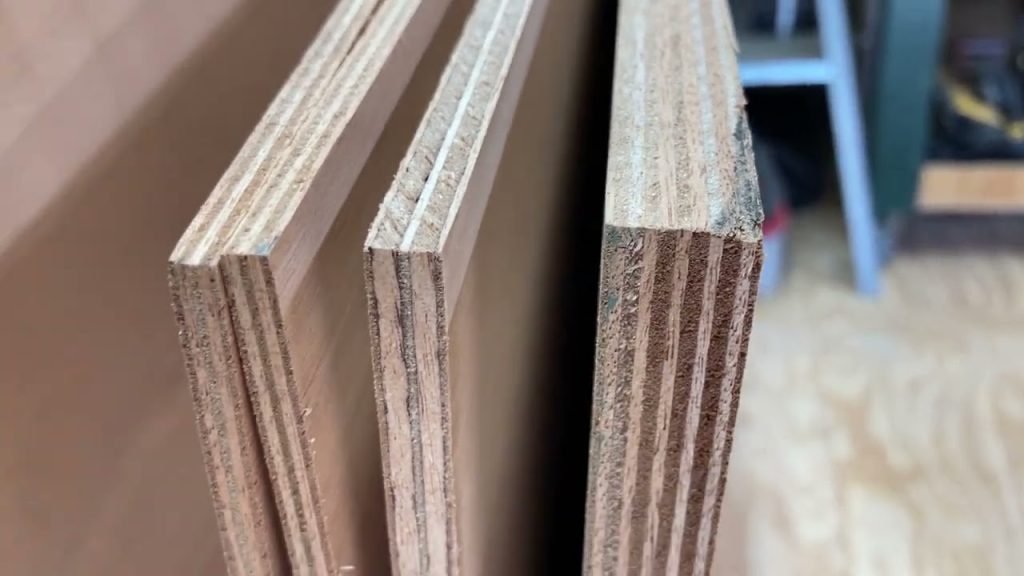

Particularly when using plywood with structural formwork, not all plywood is made equal.

Boiling Waterproof (BWP) Plywood

This variety is extremely resistant to moisture. It is perfect for concrete forming plywood because it is bonded with phenol-formaldehyde resin and remains strong in damp environments.

Shuttering plywood with a film face

Professionals highly recommend this. It has a protective coating (often brown or black) that keeps water from soaking in and guarantees smooth concrete surfaces.

Plywood of Marine Grade

Yes, it is designed for boats, but it also performs admirably on construction sites with a lot of moisture. Marine plywood is resistant to delamination and has a high strength.

Comprehending Concrete Forming Plywood

Now, let’s get a little geeky: what qualifies plywood for concrete?

Why Is It Fit for Construction?

Regular furniture plywood is not the same as concrete form plywood. Strong adhesives, cross-laminated layers, and treated surfaces are used in its manufacture. Its rigid core supports heavy loads, and its smooth texture contributes to a sleek concrete finish.

Grades and Thickness

The majority of plywood used for formwork is between 12 and 25 mm thick. The load that a sheet can support increases with thickness. For formwork projects, look for plywood with a Grade A or BWP rating.

Concrete Plywood Forms: Fundamentals of Design

Although it requires preparation, designing a plywood form is not difficult.

Panel Layouts and Dimensions

Plywood sheets are typically 8 by 4 feet. You can cut and arrange these panels to fit the size of your wall or slab. As joints are often the source of leaks and misalignment, make sure the layout minimises them.

Reusability and Surface Finish

Smooth-faced plywood is easier to strip and produces cleaner concrete surfaces. Additionally, plywood can be reused more often if it is smoother. Expert advice? To prolong its life, apply form oil prior to each pour.

Required Equipment and Supplies: Pencil and measuring tape

- Table saw or circular saw

- Screws and a drill machine

- Oil for formwork

- Strengthening bars and ties

- Bracing metal or wood

Detailed Instructions for Creating Concrete Forms

It’s time to get our hands dirty. Here’s how to use plywood to design concrete forms.

Step 1: Measurements and Planning

Measure the area you wish to cast first. Make a sketch of it. Make plans for the locations of the joints, supports, and reinforcements.

Cutting and Structuring in Step Two

Cut the plywood to the appropriate length using a saw. Here, accuracy is key, so make sure your edges are straight and clean.

Step 3: Assembly and Reinforcement

Use screws and extra wooden bracing to secure the plywood panels. To support the weight and keep it from cracking, install reinforcement bars inside.

Step 4: Stripping and Pouring

Pour the concrete once everything is ready. After the plywood has dried, carefully remove it and store it flat so that it can be used again.

Avoid these mistakes when using low-quality plywood for plywood formwork.

- Not using form oil

- Not properly bracing panels

- Cutting without taking two measurements

- Ignoring edge protection can result in early damage.

Advice for Plywood Forming Panel Maintenance

- After stripping, clean right away.

- Keep out of direct sunlight.

- Before reusing, reapply form oil.

- Before beginning any task, check the corners and edges.

Environmental Factors

Reusable concrete form plywood is a sustainable solution. Many plywood sheets are now made from certified renewable wood, and fewer replacements translate into less waste.

In conclusion

Like the unsung heroes of construction, plywood concrete forms are robust, reasonably priced, and surprisingly ingenious. Concrete form plywood is effective whether you’re working on a commercial pillar or a residential slab. You can save time, money, and the environment by getting multiple uses out of a single sheet with the right design, upkeep, and selection.

Frequently Asked Questions

1. What is the ideal plywood thickness for concrete forms?

Standard formwork typically uses 18mm to 21mm. The size of the structure and the load determine this.

2. Is it possible to reuse plywood forms?

Indeed! Film-faced plywood can be used five to ten times or more if it is kept clean and oiled.

3. What distinguishes marine plywood from shuttering plywood?

Marine plywood is water-resistant and used in high-moisture environments, whereas shuttering plywood is only used for formwork.

4. How can I stop concrete from adhering to plywood?

Before pouring concrete, apply releasing agent or form oil to the plywood surface.

5. Is plywood used to form concrete environmentally friendly?

Nowadays, a large number of plywood products are produced from sustainable forests and have earned FSC certification. Additionally, reusability reduces waste.